Does the drink taste good, is it a milk flavor, whether the product has a unique fragrance? For professional personnel, these belong to the category of the quality indicators of drinks, and as consumers, these are the most intuitive standards to detect the safety of milk drinking.

Consumers do not know how to be sterile, but they can taste the taste of milk, such as bitter, sour, you can also see the physical state of the drink, such as swelling, flow, in fact, from a professional point of view, this is the microbial index is not qualified.

What is a microbe?

Microorganisms can be understood as a very, very small person under a microscope, with the same viscera, and also have the same nutrients to keep their life, that is, they need what nutrients they need. People drink milk in order to get protein and other nutrients to strong body and muscle, but if the milk inside the microorganism, the microorganism will eat the milk inside of the nutrients, microbial reproduction ability is very strong, reproduction is very fast, the man to drink the microbial milk, drink what, yes, is the excrement of bacteria, so we see the naked eye milk deterioration, swelling package is the microbial invasion.

As a consumer, when you read this, you add new knowledge, buy milk, and buy the latest date. As an investor in the milk project, you know more clearly that the top priority of producing qualified milk drinks is to prevent microorganisms. To overcome this difficulty, your business is like a tiger with wings added. After all, milk is also a big investment, but its rate of return is also very considerable. Therefore, a long-term and stable milk production line is your indispensable way to make money.

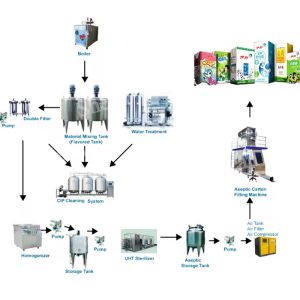

As a supplier of customers who want to purchase stable milk production lines, we are always practicing food safety and improving our solutions. On aseptic filling machine, we combined with Germany, France and the United States of aseptic technology, machine all imported appliances, imported accessories, big to pump valve, small to sealing ring, from the control of microorganisms, from the long-term operation stability of the machine, we development of aseptic filling machine has been the high praise of customers at home and abroad, this is behind the technology research and development team countless experiments and experience.

And sterilization machine in the production is also a very important link in the production of milk, milk production must use a tube sterilization machine, all the pipeline circulation, sterilization design, and design sterilization time calculation is reasonable, the pipe wall is smooth, easy to clean and so on professional issues are carefully considered.

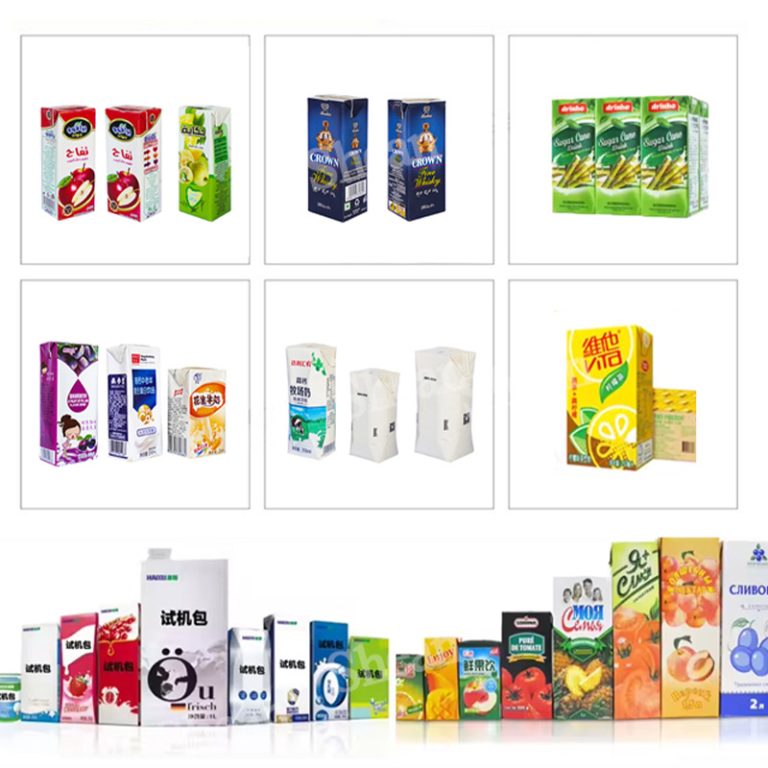

SHEAN Company professional milk and plant protein products, 20 years has accumulated a lot of successful cases, based on trust, customers to us, through our professional technical team, pre-sale consulting team and high quality installation and debugging team, let a lot of customers feel confident to us, based on trust, we let customers benefit from it, so what kind of customers to choose us? Customers with medium investment budget and customers with previous milk filling experience are suitable to choose our aseptic filling machine and aseptic sterilization and milk pretreatment equipment. Regarding the production capacity, the 200ml filling machine stabilized the filling speed at 5000-5400 boxes per hour.

Choosing SHEAN can make your product quality stable and bring you a steady stream of money.