plant-based coconut beverage- coconut milk . This delightful drink not only tantalizes your taste buds but also offers a wealth of nutritional benefits, making it an ideal choice for health-conscious individuals.This is popular choice in southeast and China.because

coconut beverage is completely Coconut pulp (juice) and (or) coconut pulp after sq

ueezing coconut pulp as the main raw material,The beverage product prepared through blending, sterilization, filling and other processes has a soluble solid content ≥8.5g/100g, protein ≥0.55g/100g, and fat ≥2.5g/100g. ensuring that it accommodates a wide variety of dietary preferences and restrictions.

Since there are high protein contents and fat inside of coconut beverage,then how to fill such tasty beverage into tetra paper cartons?

Just utilize advanced aseptic filling technology in to your production process.

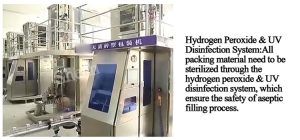

Carton filling machine is an efficient automatic production line that can complete paper feeding, sterilization, box making, filling, forming and sealing processes at one time. The composite material sterilization technology combines hydrogen peroxide spray, high intensity ultraviolet radiation and sterile hot air drying to ensure the sterile state of packaging materials and materials.

Sheanpak aseptic filling machine adopts a four-step sterilization process that guarantees the beverage is free from harmful microorganisms.In a sterile room with positive pressure conditions, the molding of packaging paper, material filling and sealing after filling are carried out in a strict sterile environment, which can ensure that the shelf life of UHT (ultra-high temperature) sterilization treatment can be up to one year at room temperature.

In addition, the equipment of each system are adopted the Germany, Japan and other countries of advanced brand components, including PLC control system, photoelectric correction system,

frequency conversion speed control device, pneumatic solenoid valve, vacuum system, liquid level control, intelligent electronic temperature control regulation, the automatic fault alarm system, etc., to ensure the stability and reliability of the equipment. The whole machine is made of stainless steel material, not only exquisite in appearance, but also convenient to operate, in line with the hygiene and safety standards of modern food production.

Also make sure your coconut process is safe and keep 12 months shelf time. This meticulous method ensures that every sip you take is not only enjoyable but also safe and healthy.

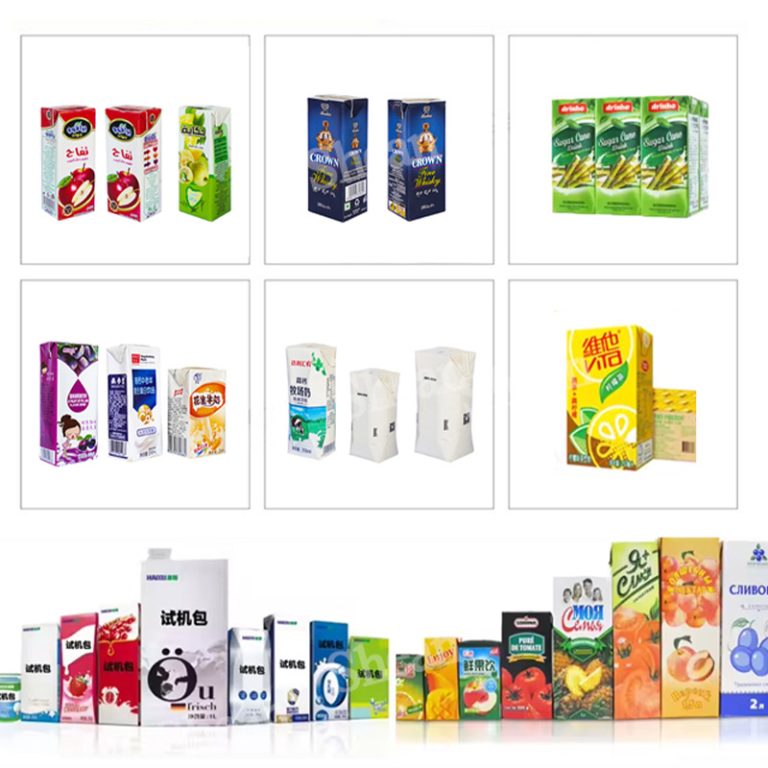

Due to different usage scenarios, the carton sizes are 125ml, 200ml B, 200ml S, 330ml prisma, 500ml prisma, 1L prisma, 1L Brick, 1L Stand. Our aseptic coconut milk filling machine can fully meet your different needs. Usually, the output of carton filling machines below 500ml can reach 5600 per hour, while the filling output of 1L is 3000 per hour. It fully meets the dairy filling needs of a small and medium-sized enterprise.

| Device model | SHB 5600-200S | production capacity | 3000 cartons/hour |

| Packing capacity | 1000 ml | power supply | Three-phase electricity

380V/220V 50Hz |

| compressed air pressure | ≥0.6MPa(6Bar) | total power | 25KW |

| Dimensions | 4000mm*1930mm*3950mm | Actual power consumption | 19KW |

| Total Weight | 2970Kg |