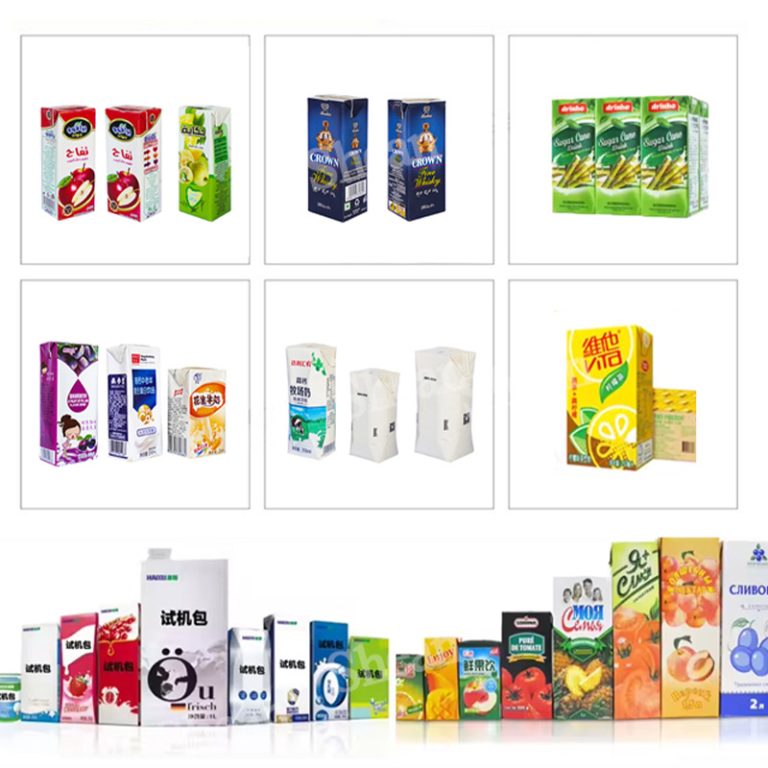

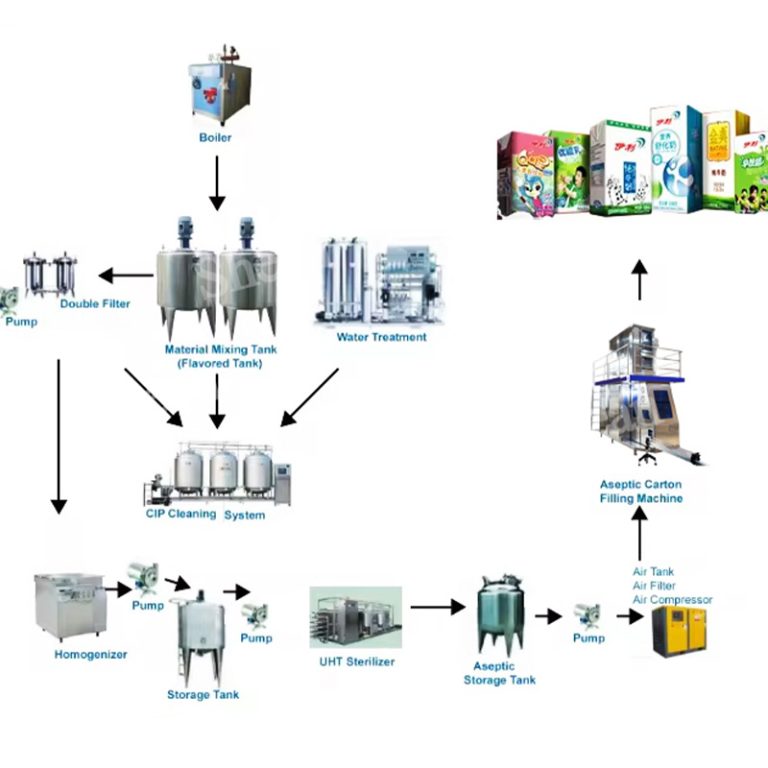

In the modern beverage market, whether abroad or in China, whether fresh juice, paper packaged juice or plastic bottled juice consumers have higher and higher requirements for the taste and safety of drinks. Therefore, the choice of suitable processing and packaging solutions becomes crucial.

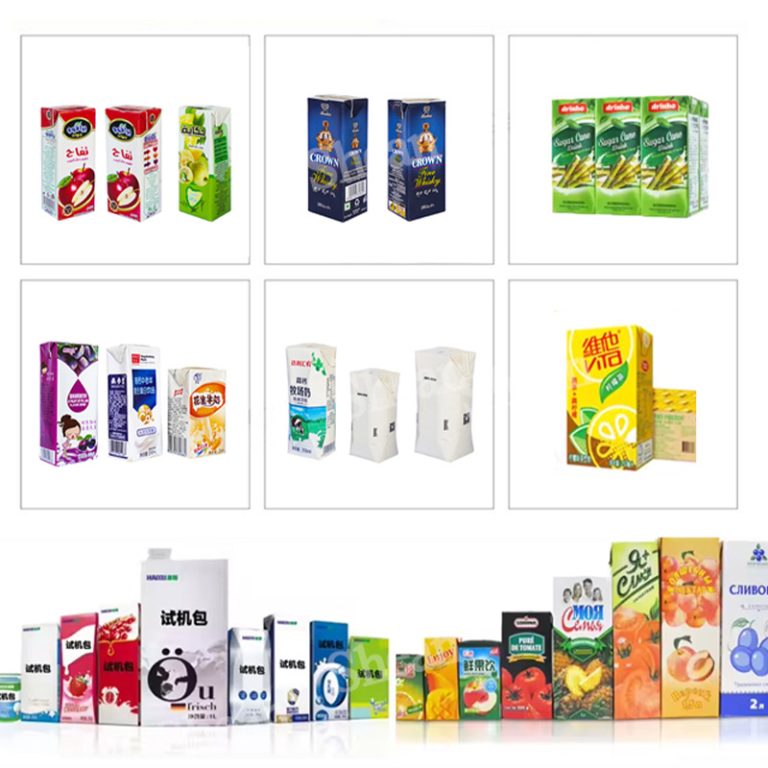

Formula is the most important factor for juice,there are different tastes from 10% to 40% NFC; some juice producers may add some pulp to fill the juice to improve quality. Noble juice will be the high-end people of the market, and then bring considerable market benefits.

In the modern beverage market, whether abroad or in China, whether fresh juice, paper packaged juice or plastic bottled juice consumers have higher and higher requirements for the taste and safety of drinks. Therefore, the choice of suitable processing and packaging solutions becomes crucial.

Formula is the most important factor for juice,there are different tastes from 10% to 40% NFC; some juice producers may add some pulp to fill the juice to improve quality. Noble juice will be the high-end people of the market, and then bring considerable market benefits.

SHAN works closely with you to use our lab to develop unique drink recipes for you and design efficient production processes. With our technology and experience, you can ensure that every drink maintains its original flavor and nutrients and meets consumer taste preferences.

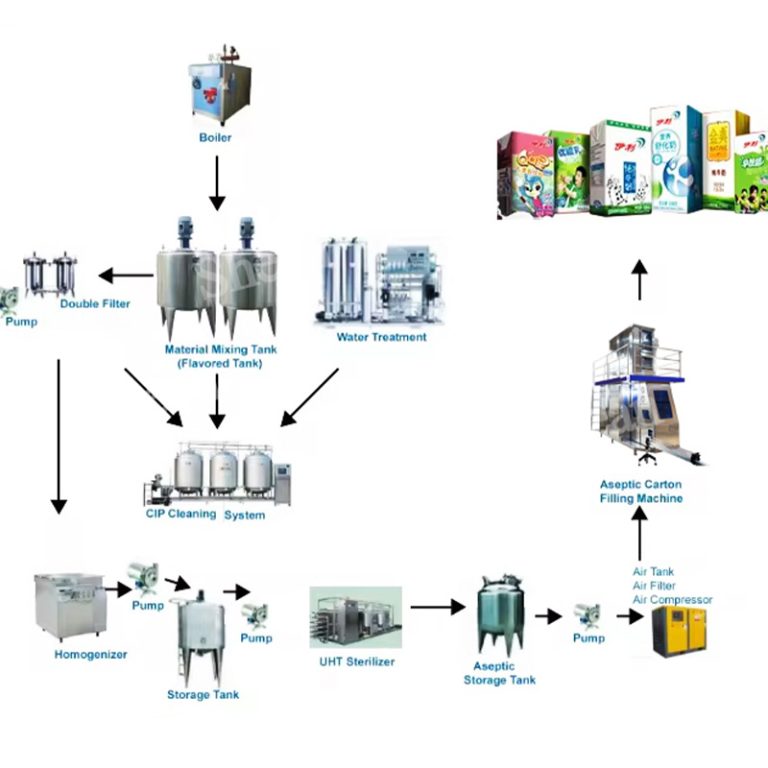

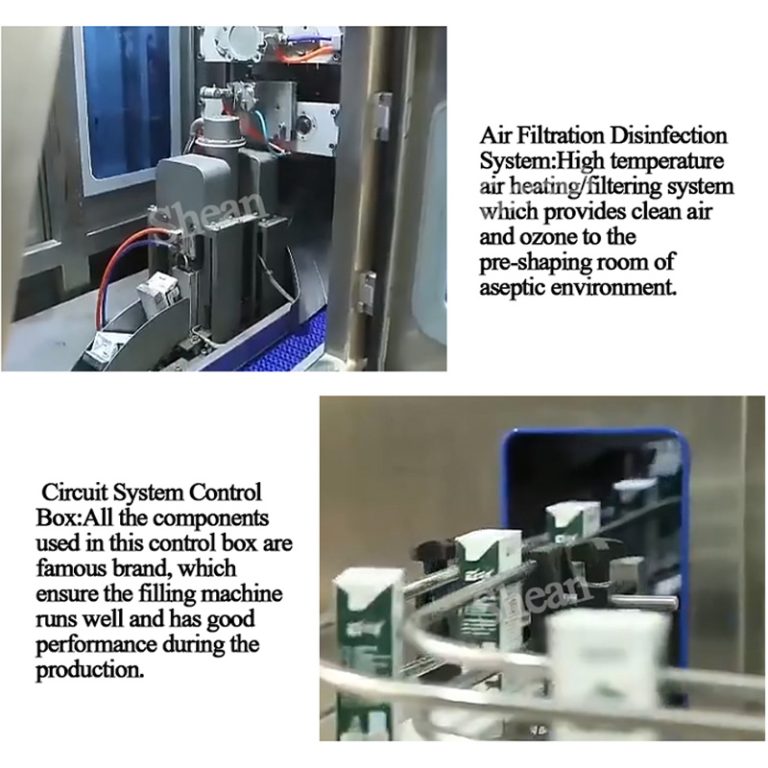

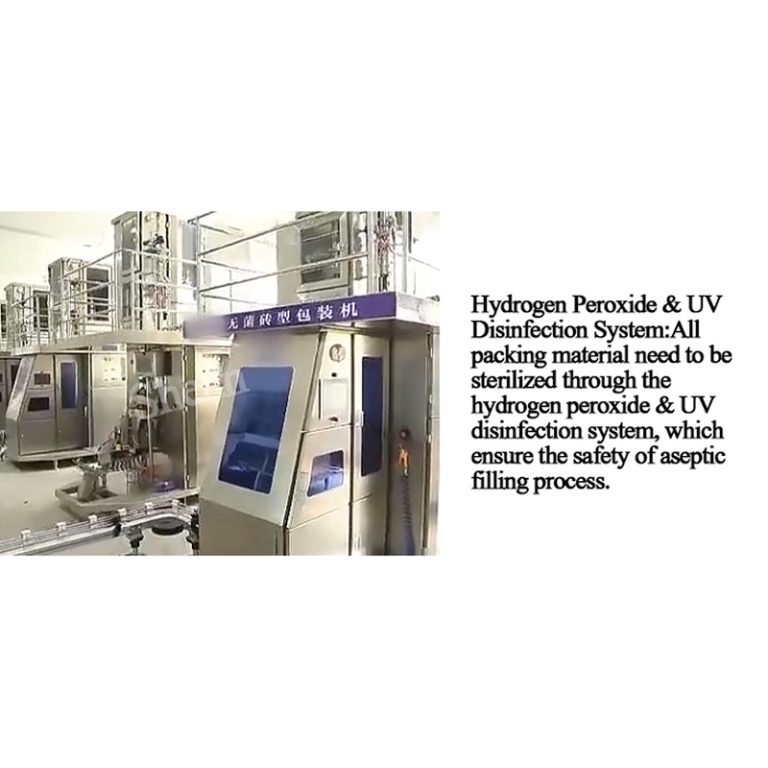

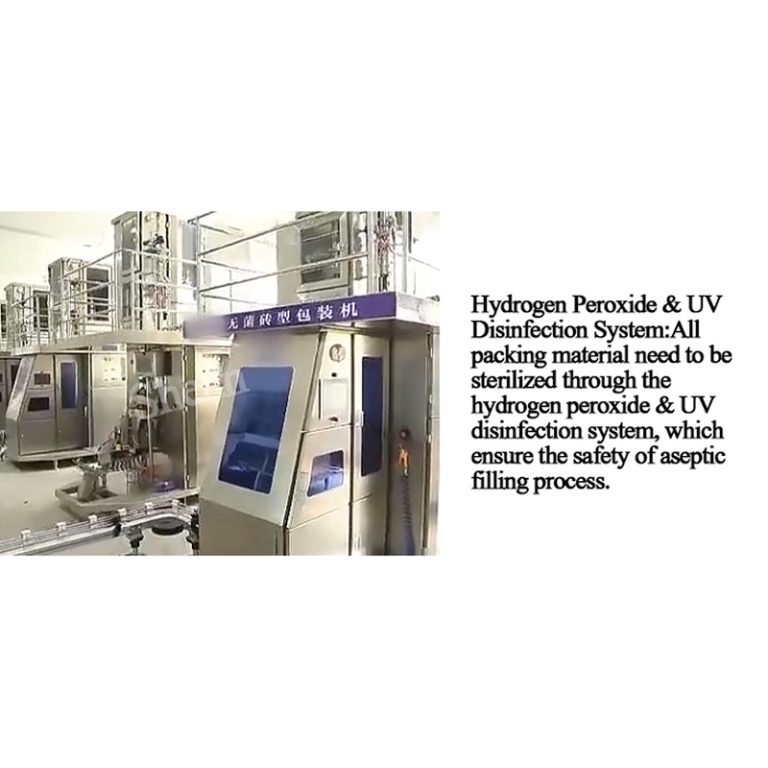

In order to produce high quality, good taste of pure fruit juice, then aseptic filling is very important. The sterilization is not complete, can not guarantee the quality of the product, the most common problem is that the juice will be contaminated by microorganisms, swelling package, bad bag, juice deterioration problem. Once these problems appear, they will have a great impact on the juice manufacturers. The reason is the lack of understanding of the aseptic filling machine and the whole pretreatment, no correct understanding of the sterilization principle of the aseptic filling machine, no correct judgment, and the selection of poor quality equipment leads to trouble.

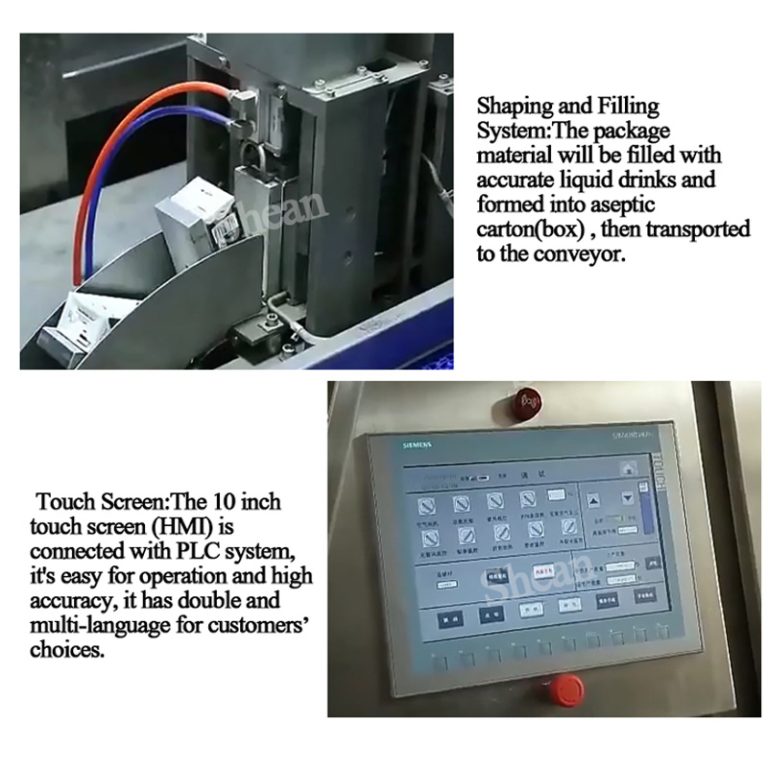

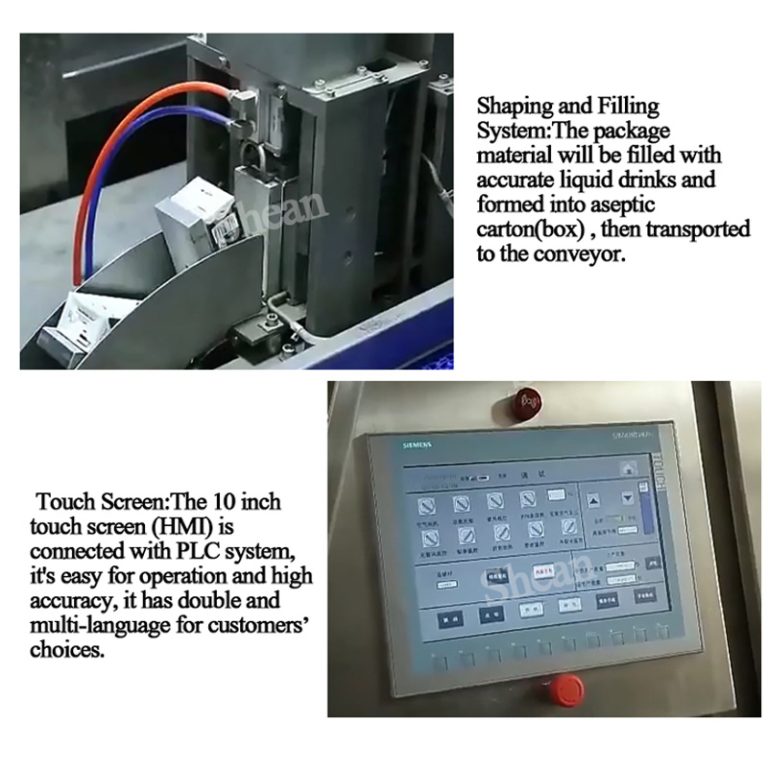

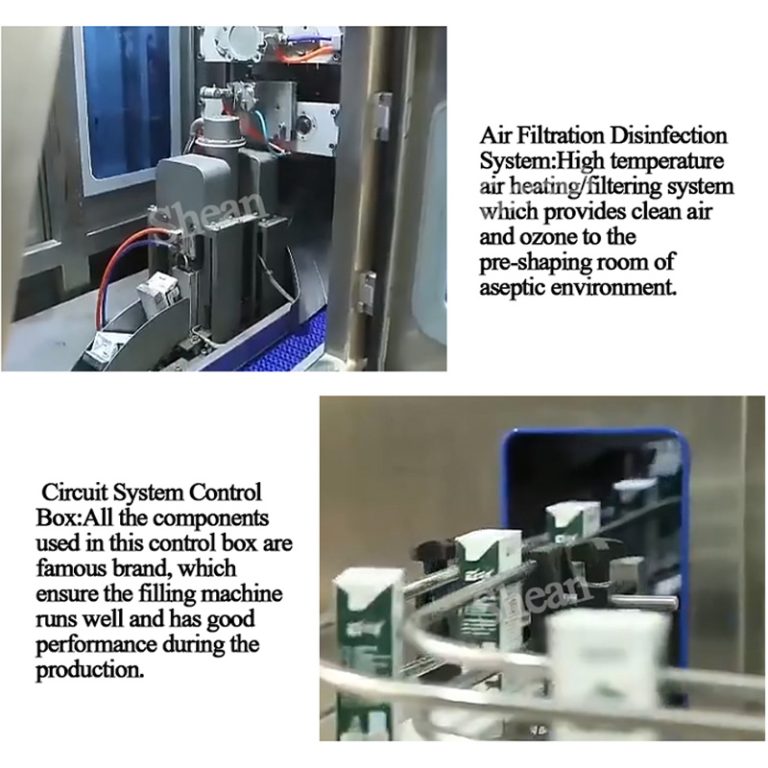

To produce 40% content, good taste, long shelf life juice, you have any doubts, you can consult us for free. Our aseptic filling machine 4 heavy sterilization effect, simple operation, low maintenance cost, efficient production and energy saving.

Whether you are a newcomer to the beverage market or an experienced industry veteran, we can provide you with the professional support you need. With our aseptic filling technology and customized processing solutions, you can confidently launch a range of high-quality drinks to meet market demand. Let’s turn your drink dream into reality and create the ideal refreshing drink in the eyes of consumers. Learn more about our beverage processing and packaging solutions to start your journey to success.

| Device model | SHB 5600-200S | production capacity | 5600cartons/hour |

| Packing capacity | 200ml | power supply | Three-phase electricity

380V/220V 50Hz |

| compressed air pressure | ≥0.6MPa(6Bar) | total power | 25KW |

| Dimensions | 4000mm*1930mm*3950mm | Actual power consumption | 19KW |

| Total Weight | 2970Kg |

Feature of Machine

we are free to support you

Shean ( Cangzhou) Corp Ltd .

©2024 Shean ( Cangzhou) Corp Ltd which., All Rights Reserved.